Revolutionizing Clean Energy: Exploring Siemens Hydrogen Electrolyzer

Advancing Sustainable Solutions

Siemens Hydrogen Electrolyzer stands at the forefront of innovation in the clean energy sector. With a strong commitment to sustainability, Siemens has developed cutting-edge electrolysis technology that converts electricity and water into clean hydrogen gas. This process offers a promising pathway to decarbonize various industries, including transportation, manufacturing, and energy production.

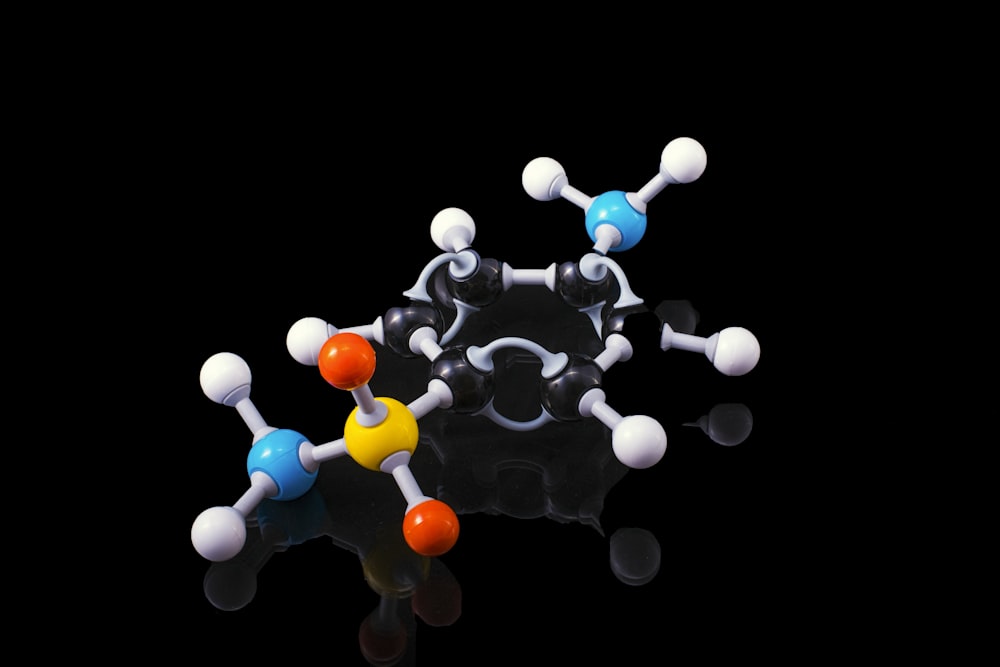

The Power of Electrolysis

At the heart of Siemens Hydrogen Electrolyzer lies electrolysis, a process that splits water molecules into hydrogen and oxygen using electricity. Siemens’ advanced electrolyzer technology utilizes renewable energy sources such as solar and wind power to power this process, resulting in zero-emission hydrogen production. By harnessing the power of electrolysis, Siemens is enabling the widespread adoption of hydrogen as a clean and versatile energy carrier.

Efficiency and Reliability

Siemens Hydrogen Electrolyzer is renowned for its efficiency and reliability. The company’s electrolyzer systems are designed to operate at high efficiency levels, maximizing hydrogen production while minimizing energy consumption. Siemens’ electrolyzers also boast long lifespans and minimal maintenance requirements, ensuring reliable operation and minimal downtime for end-users. With a focus on performance and durability, Siemens is setting a new standard for electrolyzer technology.

Scalability and Flexibility

Siemens Hydrogen Electrolyzer offers scalability and flexibility to meet the diverse needs of customers and industries. Whether it’s a small-scale electrolyzer for onsite hydrogen production or a large-scale system for industrial applications, Siemens has a solution to fit every requirement. Furthermore, Siemens’ electrolyzer technology is compatible with a wide range of renewable energy sources and can be integrated seamlessly into existing energy infrastructure, providing flexibility and versatility for end-users.

Applications Across Industries

Siemens Hydrogen Electrolyzer has applications across various industries, from transportation to manufacturing to energy storage. In the transportation sector, hydrogen produced by Siemens’ electrolyzers can be used to power fuel cell vehicles, offering zero-emission mobility solutions. In manufacturing, hydrogen can be used as a clean fuel for heating, cooling, and power generation, reducing carbon emissions and improving air quality. Additionally, hydrogen produced by Siemens’ electrolyzers can be stored and used for grid balancing, providing a reliable and flexible energy storage solution.

Environmental Benefits

Siemens Hydrogen Electrolyzer offers significant environmental benefits compared to conventional hydrogen production methods. By using renewable energy sources to power the electrolysis process, Siemens’ electrolyzers produce hydrogen with zero carbon emissions, helping to mitigate climate change and reduce air pollution. Additionally, Siemens’ electrolyzers help reduce the reliance on fossil fuels and promote the transition to a low-carbon economy, contributing to a cleaner and more sustainable future.

Commitment to Innovation

Siemens is committed to driving innovation in electrolyzer technology to further improve efficiency, reliability, and cost-effectiveness. The company invests heavily in research and development to develop new electrolyzer designs, materials, and manufacturing processes. Siemens collaborates with industry partners, research institutions, and government agencies to advance the state of the art in electrolysis technology and accelerate the adoption of hydrogen as a clean energy solution. With a relentless focus on innovation, Siemens is shaping the future of clean